Leading the Way in Sustainable Solutions

At Formcase, we believe that sustainability is not just a goal; it's a responsibility.

As a leading provider of Charging Solutions, we are committed to integrating eco-friendly practices into every facet of our operations.

Sustainable Materials and Production

Our product is made from carefully selected sustainable materials. We emphasize ecologically sound raw materials that are either recyclable, biodegradable or from renewable sources. In addition, we make sure that production processes are as resource-efficient as possible to minimize the ecological footprint.

Durability and Reusability

Our product is designed to have a long service life. By using high quality materials and careful workmanship, we ensure that it can withstand daily wear and tear. In addition, we promote the reusability of our product to reduce waste and minimize the consumption of disposable products.

Environmentally Friendly Packaging

We are aware that packaging makes a significant contribution to the waste problem. That’s why we focus on environmentally friendly packaging solutions. Our packaging is made of recycled or biodegradable materials and is designed to ensure transport and storage protection without creating unnecessary waste.

Transparent supply chain and social responsibility

We attach importance to a transparent supply chain and cooperate with suppliers who meet our high sustainability standards. We promote fair working conditions and social responsibility along the entire value chain. Through our responsible sourcing, we help to achieve positive social impacts.

Customer Awareness and Education

Our goal is not only to offer sustainable products, but also to promote awareness and education. We inform and inspire our customers about the benefits of a sustainable lifestyle and provide practical tips for an environmentally conscious everyday life. By sharing knowledge, we want to help promote a sustainable mindset and bring about change in society.

Energy Efficiency

Our facilities are equipped with state-of-the-art technology to ensure energy efficiency. From manufacturing processes to office spaces, we are constantly striving to reduce our energy consumption and adopt renewable energy sources.

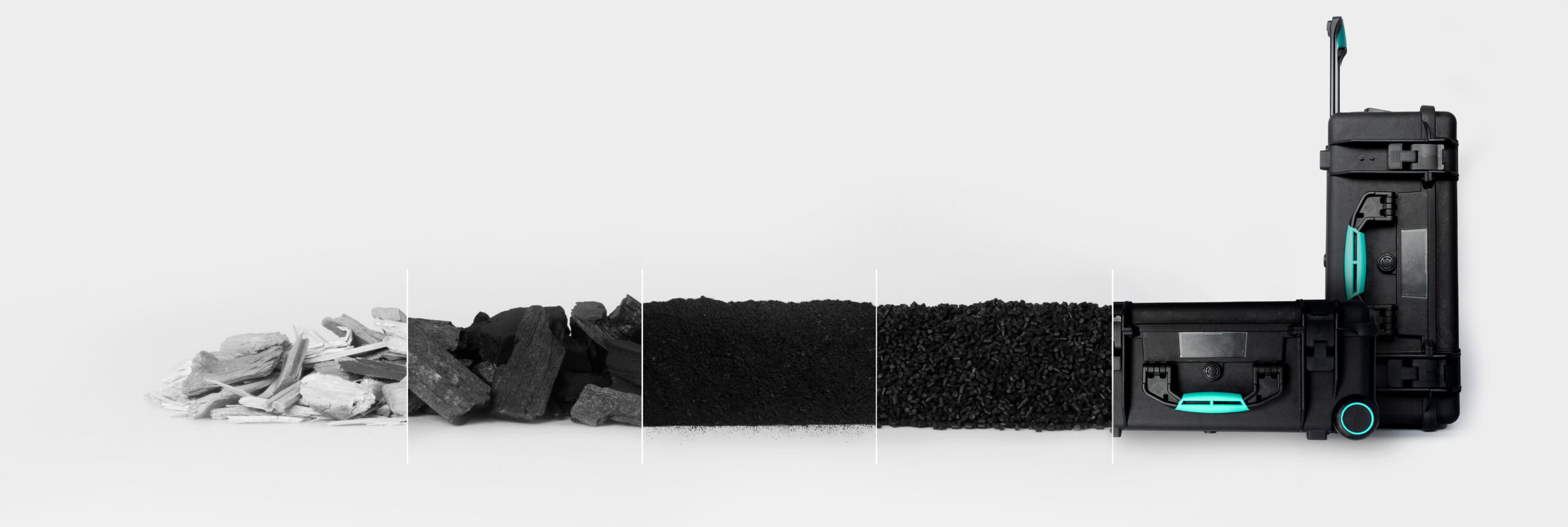

Formcase CO2 Minus Mission

As part of our commitment to sustainability, we take into account all possible environmental aspects in the manufacture of our products.

A sustainable material – polypropylene (PP)

“Polypropylene is a premium material. The return of the polypropylene material from the interlayers to the manufacturing process is always safe. The use of polypropylene ensures full recyclability at the end of the product life cycle. The recycled material is used to make new products, minimizing the spread of pollutants in the environment.”

Polypropylene (polypropylene or PP) has a long history. In Germany in 1954, Karl Rehn, discovered this material from the “Farbwerke Hoechst”. At the same time, the material was synthesized and industrially produced by the scientist Giulio Natta in Italy. It is a thermoplastic with high stability and chemical resistance. However, it is harder and more heat resistant. It can be heated to 140° C for a short time. Coffee makers and kettles are usually made of PP. If the temperature drops below 0° C, the material can become brittle. To avoid this, there are so-called copolymers with ethene.

The special feature of polypropylene is its tacticity, i.e. the order of the methyl radicals during polymerization. Depending on the arrangement of the methyl residues, the polymers are divided into three groups. Tacticity is also partly responsible for the properties of the plastic. Therefore, the type of tacticity is decisive for the quality of a polypropylene.

Polypropylene is a thermoplastic, i.e. the granules (small grains) are heated until they are liquid and shaped. After cooling, the polymer emerges in its new form, e.g. as a cup.Thermoplastics, also called plastomers, are plastics that can be deformed (thermo-plastically) within a certain temperature range. This process is reversible, i.e. it can be repeated as often as desired by cooling and reheating to the molten state, as long as the so-called thermal decomposition of the material does not set in due to overheating.

What is polypropylene? (PP)

Polypropylene (PP) is a thermoplastic consisting of ethylene and propylene. Plasticizers are not used, which is not harmful to health. Thermoplastic means that polypropylene (PP) can be deformed by heat as many times as required and can be desired shape. This predestines polypropylene (PP) as a basis for packaging and, right after PE, it is the most frequently used plastic for the packaging industry. Polypropylene (PP) is manufactured by polymerization, a gas which is produced during the petroleum processing.

Why is polypropylene sustainable? (PP)

The reason why polypropylene (PP) is sustainable is that it is very durable and is created for long use. This means that products made of polypropylene (PP) do not need to be constantly replaced in order to protect the environment. Accordingly, however, polypropylene (PP) also has the property of not decomposing. Nevertheless, polypropylene (PP) is more environmentally compatible than other plastics. This is because polypropylene (PP) hardly forms any pollutants in nature that could contaminate the groundwater or damage the environment.